Waterers, drinking troughs

For high productive animals it is necessary to supply sufficient quantity of water. On average, cows drink 80 litres of water every 24 hours, and when it is warm high-yielding cows can drink 120 - 150 litres of water. Water is necessary for the breakdown of feed and for thermoregulation of the cows.

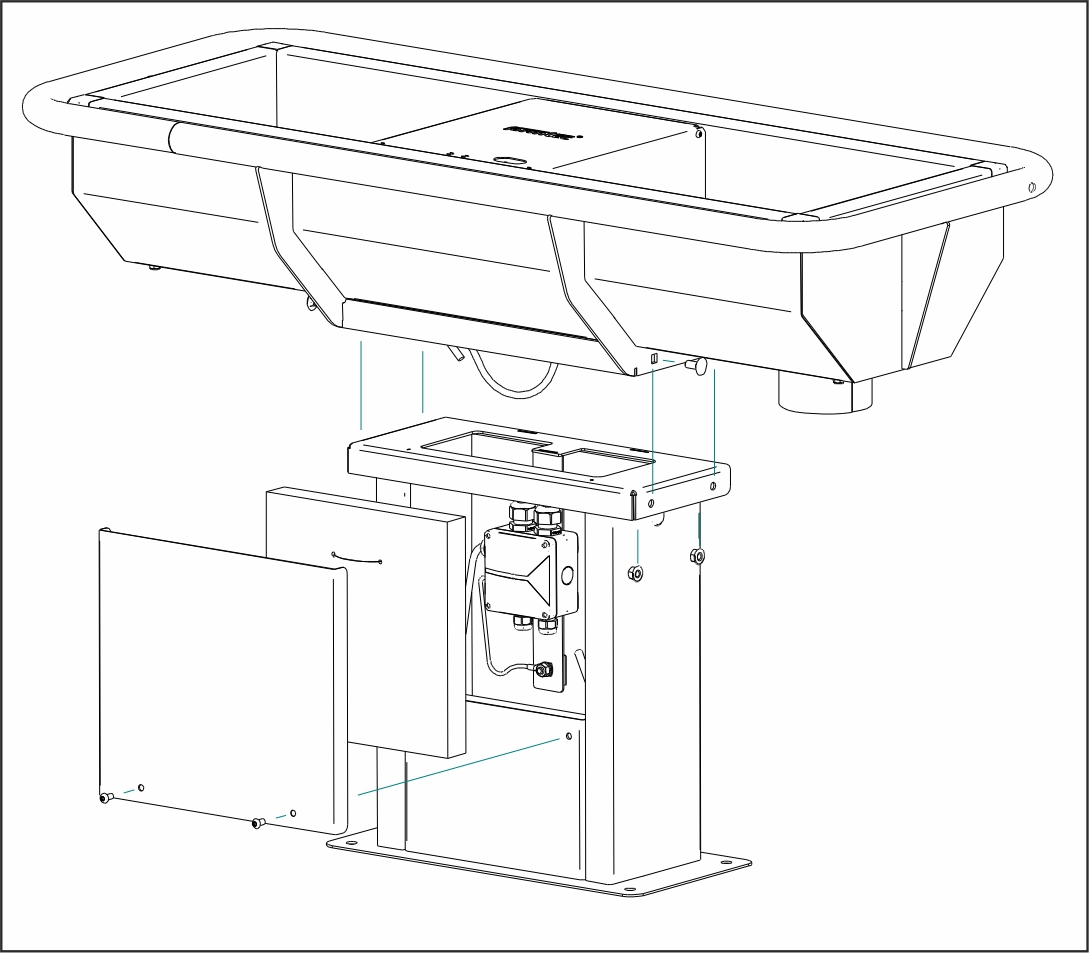

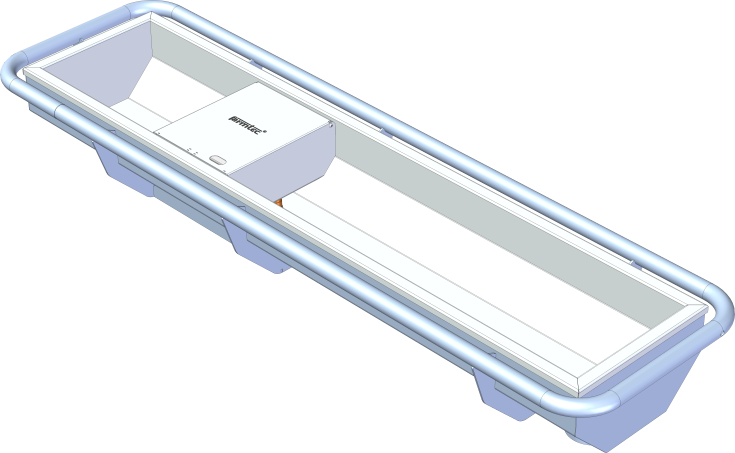

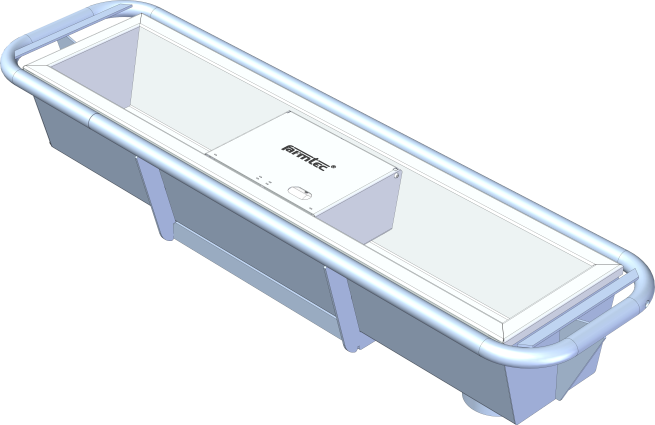

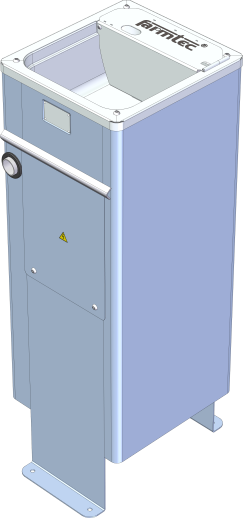

Waterers III. generation (available from May 2020) consists of two separate parts. From the trough foot (can be hot-dip galvanized Z or stainless steel N and in versions for installation into or on concrete) and the trough body (this consists of a hot-dip galvanized skeleton and a stainless steel tub with water surface).

Our drinking throughs are suitable for all categories of cattle, sheep and goats. We offer Heated stainless steel waterers / drinking troughs with plug.

The main advantages of our heated stainless steel waterers / drinking troughs are:

Our waterers don't freeze in winter

- The heated cable is located in the double bottom of the waterer, then in the leg of the waterer on the water inlet.

- The intake valve can't freeze because it's located under the water surface, which is heated.

- The waterer's leg and body are insulated with polystyrene and mineral wool insulation.

- While the electricity works, the waterer doesn't freeze - in operating tests up to - 20 °C.

- Supply voltage 230 V / 50 Hz.

You don't lose hectolitres with our waterers when cleaning

- Water savings - the waterers have a volume corresponding to the need for animals (drinking from the loose surface level) in relation to the feeding speed.

- The inlet valve flow rate is about 0.3 MPa (3 atm) to 50 l/min on a water line pressure.

Quick and easy cleaning of our troughs

- The entire inner surfaces of the waterer under water (walls and bottom) are accessible, smooth and unobstructed.

- It's also easy to clean the float chambers - the stainless steel enclosure prevents animals from accessing the float, but the operator is able to open the cover quickly and easily without tools.

- A large drain plug - coarse dirt is slightly rinsed after draining and water drains rapidly.

- It's possible to select a left or right location for the drainage spout, when cleaning the waterer the drainage water can also be connected directly to the sewer.

Robust construction of our troughs and long service life

- The waterer's outer structure is hot dip galvanised, the inner part (where the water is), is made from stainless steel.

- Waterers can be made in a stainless steel version, especially suitable for deep beds and for places where the waterer's leg is permanently in contact with slurry.

- The waterers are directly anchored to the concrete, it's important that the height corresponds with the height for the given category of animals (recommended feed levels are given in the instruction manual).

- The alternative is the waterer's location on ready-made concrete, there is a need for height adjustment of the waterer leg – it's adjusted to height according to the category of animals and an anchor part is needed - a collar for the leg, is firmly connected to the concrete with chemical anchors and screwed to the waterer . It's always necessary to seal the water and electricity supply properly and prevent access to animals and rodents.

- Opposed to tilting waterers, FARMTEC waterers aren't burdened by constant tilt movement, there is no open space anywhere. If the quality of the concrete is maintained, there is no risk of rodents getting into the waterer, which, together with the tilting waterer's poor closure, is the most frequent problem with tilting waterers.

- Waterers FARMTEC type JUPITER 4136 kB

- Waterers FARMTEC type NEPTUN 3385 kB

- Waterers FARMTEC type MERKUR 1726 kB

- Waterers FARMTEC type TRITON 3320 kB

- Waterers FARMTEC III 4279 kB

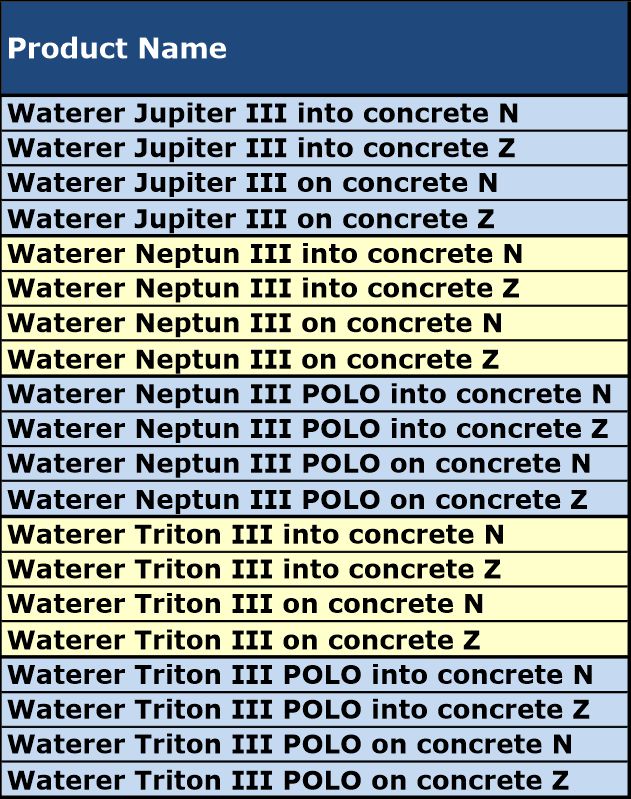

Technical stats of stainless steel drinkers:

| MJ | JUPITER MAX | JUPITER DUO | JUPITER | NEPTUN |

NEPTUN POLO |

TRITON |

TRITON POLO |

MERKUR | |

|---|---|---|---|---|---|---|---|---|---|

| Wide | [mm] | 600 | 600 | 600 | 600 | 600 | 385 | 385 | 400 |

| Length | [mm] | 3170 | 2500 | 2120 | 1420 | 990 | 1450 | 1030 | 355 |

| Height | [mm] | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 | 1050 |

| Internal volume | [l] | 200 | 160 | 130 | 80 | 52 | 38 | 25 | 13 |

| Tributary (press 300 kPa) | [l/min] | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 13 |

| Weight | [kg] | 110 | 95 | 88 | 61 | 46 | 47 | 35 | 35 |

| Voltage | [V] | 230 | 230 | 230 | 230 | 230 | 230 | 230 | 230 |

| Input | [W] | 416 | 356 | 256 | 216 | 116 | 136 | 96 | 60 |

| Covering | [IP] | 55 | 55 | 55 | 55 | 55 | 55 | 55 | 55 |

| Deep (MAXIMAL) | [mm] | 260 | 260 | 260 | 260 | 260 | 170 | 170 | 140 |

| Cattle (maximal count 1pcs=600 kg) | [pcs] | 60 | 45 | 40 | 30 | 15 | 30 | 15 | 15 |